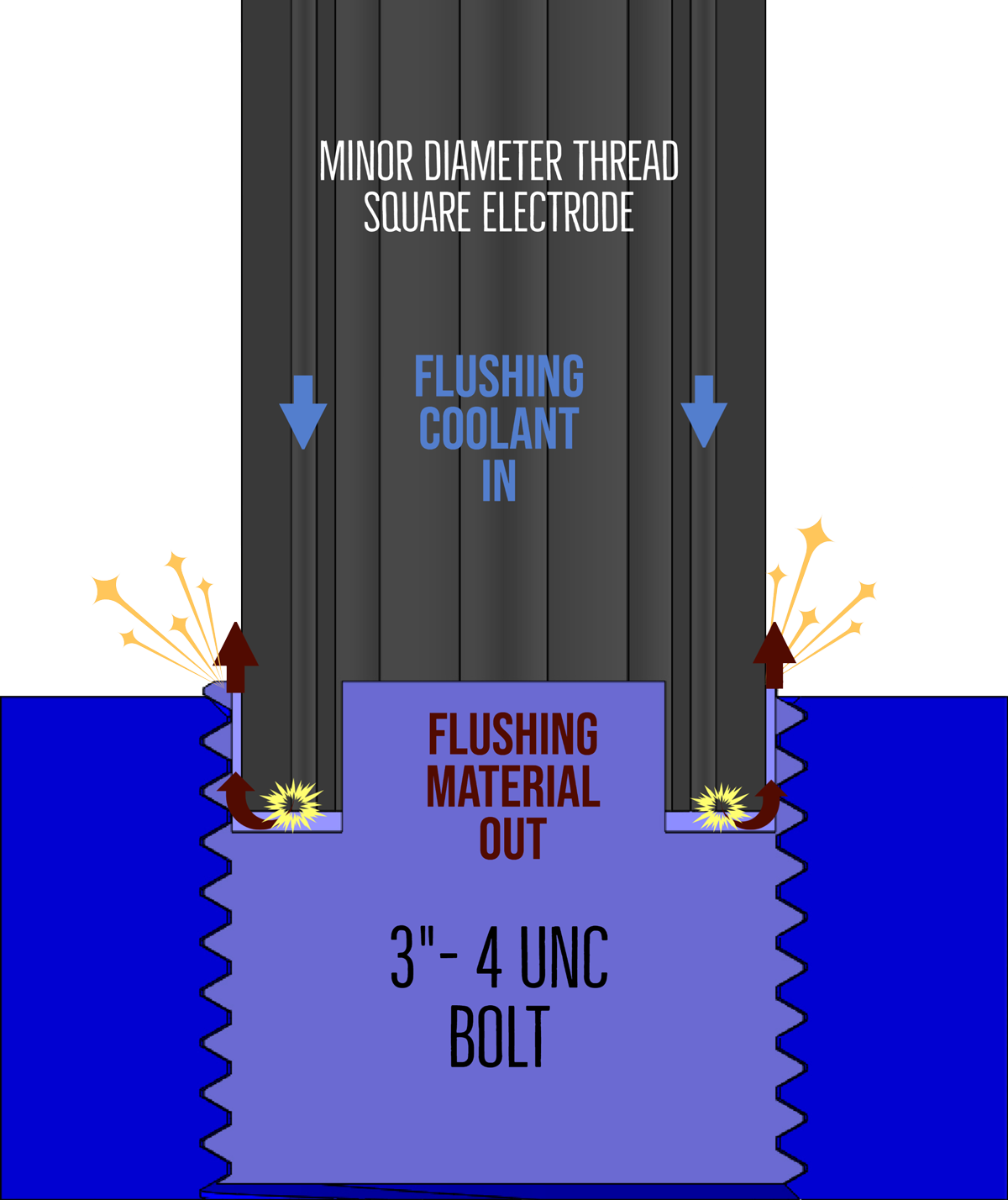

An electrode, held in the cutting head of the disintegrator, vibrates to create precise cuts while a coolant is pumped through the electrode to wash away the powdered metal and keep the part cool. Metal disintegrators manufactured by Cammann Inc. are primarily used for tap removal, stud removal, drill removal and seized or broken bolts.

About Metal Disintegration

The cutting action of a metal disintegrator is accomplished by creating a series of intermittent electric arcs that break down the hardest metals into minute particles.

See Our Machine in Action

A Look at the Process

1

Tap broken off in threaded hole.

2

Center SQSS cutting head and electrode over hole.

3

Disintegrated tap.

4

Remove core.

5

Remove tap cutting flutes (1).

6

Remove tap cutting flutes (2).

7

Remove tap cutting flutes (3).

8

Remove tap cutting flutes (4).

9

Clean and retap the threaded hole.

10

End result.